|

|

|

MSC Method - Miracle Sludge Clean Method -

■Let's clean contaminated rivers, lakes/marshes and seas!!

In rivers, lakes/marshes and seas, bottom mud is being deposited in the

bottom for a long time due to the inflow of domestic sewage and sand. This

bottom mud (organic mud:sludge) will not only cause water quality to detoriate

but will also interfere with the degradation of water storage volume, water

flow rate and ship navigation. During summer, as the water temperature

rise, nitrogen and phosphorus will increase, that will lead to eutrophication.

Moreover, the massive outbreak of algal bloom due to photosynthesis causes

water contamination and releases a bad odor.

Bottom mud treatment technology with MSC method can quickly and economically

improve large amount of bottom mud to good quality soil by its flocculation

ability, dehydration separating action and aggregation function. Suspended

solids, BOD, nitrogen and phosphorus are removed from the water through

this advanced treatment. Since MSC does not have a negative impact on the

Ecosystem, it also creates suitable environment for fish and aquatic organisms.

|

Characteristics |

1. It is confirmed that treated water and soil are safe

2. It has deodorization and sterilization effects

3. It can re-use the treated soil for plants because it is harmless

4. It can cut time and cost because the processing speed is fast

|

Applications |

・Bottom mud treatment for lakes/marshes, rivers and dam

・Treatment for deposited bottom sludge and contaminated water

・Treatment for deposited bottom sludge and contaminated water in the sea

・Treatment for sludge and contaminated water from industry disposal

・Treatment for sludge and contaminated water from agriculture

・Treatment for sludge and contaminated water from sewage

Environmental maintenance construction at the moat of Joshi park in Takasaki

city Environmental maintenance construction at the moat of Joshi park in Takasaki

city

Dredging range:431.8m、 Amount of dredging sludge:1,081m3

Construction: SO-EN CO., LTD Planning: (NPO) Japan Water Guard

With iron salt and metal salt as its main components, this method is carried

out by using an inorganic coagulant made out from rare earth elements called

"MSC" for bottom mud treatment and water purification technology

.

As hydrophobing dehydration treatment and soil stabilization additive,

MSC facilitates dredge bottom mud precipitation and consolidation fast,

as well as purify the separated water.

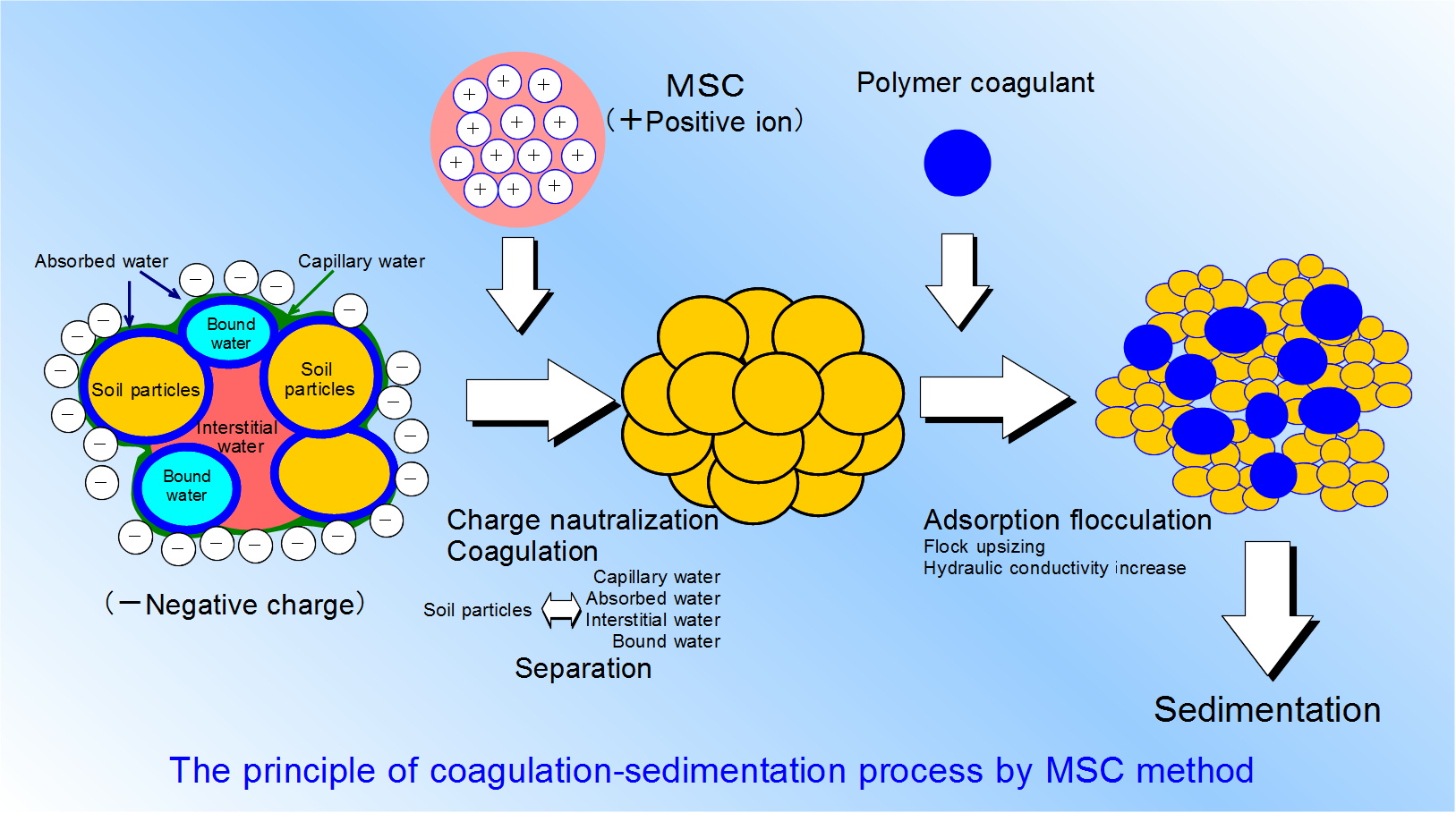

The structure of sludge consists of fine particles which aggregates to

mineral particles. The spaces between fine particles will be filled with

water and air and these soil particles usually have negative charge.

By adding MSC, MSC electrically neutralizes the negative charge of soil

particles because MSC is a positive ion substance. During this time, capillary

water combined with soil particles is separated. Then, interstitial water

and a film of absorbed water will become free. By this hydrophobing phenomenon,

soil particles will adsorb each other and the particle diameter becomes

bigger, that leads to sedimentation. By adding the polymer flocculant,

the diameter of flock gets bigger and it will settle down very fast.

This flocculation sedimentation soil has large hydraulic conductivity

by a hydrophobing phenomenon of soil particles. It enables to conduct effective

dehydration of bottom sludge and will improve the dehydration of the soil

easily.

Principles

| ① |

By adding MSC to the bottom sludge or contaminated water, absorbed water

film is destroyed due to hydrophobing. Also, capillary water between soil

particles is separated and becomes free water. Separated soil particles

adsorb each other, thus become gritty particles. |

② |

In adding high-polymer coagulant, the diameter of flock gets bigger, and

it settles down very fast. |

③ |

Flocculated soil particles are not mixed with water again. As a result,

supernatant water can directly drain. By filtering with permeable mats,

the water is easy to be separated. |

④ |

Flocculated soil has large hydraulic conductivity by hydrophobing of soil

particles. Thus, it enables to conduct efficient dehydration in bottom

sludge. Moreover, because soil particles are absorbed each other without

capillary water, the bonding structure is strong and has large consolidation

strength. As a result, the soil for landfill can be re-used for its good

quality. |

|

| Raw sludge water before procesing |

MSC Added |

Polymer coagulant added |

Treated water |

Specific characteristics of MSC method

1.Sedimentation Velocity:

Flocculation sedimentation velocity with MSC is several times faster than

conventional flocculant.

2.Separated water quality:

Suspended substances (SS) and organic material in the water are separated

by flocculation sedimentation and the separated water is purified as clean

water.

3.Water content of flocculation on separated soil:

Flocculation separated soil quickly becomes hydrophobic and they are able

to be transportable water content by rapid drainage between soil particles.

4.Consolidation characteristics of flocculation separation soil:

Flocculation separated soil becomes hydrophobic and interstitial water

rapidly drains. The frame of soil particles itself is easy to be compressed

and shows large coefficient consolidation .

5.Safety:

Since it does not contain toxic substance, the separated water, coagulation

and sedimentation soil is safe and harmless to organisms, plants and environment.

Advantage in actual construction

1.Improvement on the dredger's operation rate:

Since MSC method conducts the process that automatically provides MSC

and polymer flocculant mixing them in the sludge pipes, it speeds up solid-liquid

separation. Even in small capacity and when the flow-down distance is short

to the sludge disposal pond, it can perform solidification fast in a short

period of time. Good workability and can cut down dredging operation cost.

2.The early use of reclaimed land

You can conduct initial sedimentation of dredging separation soil and

self-weight consolidation more quickly than the conventional method.The

soil can be easily taken out and transported by a dump truck. In addition,

it enables to obtain high consolidation strength in the reclaimed land

and landfill. You do not need to construct ground reform and you can use

the dredged reclaimed land quickly.

Principal component of MSC is iron salt (mainly ferric chloride) and metal

salt (mainly aluminum sulfate), and MSC includes inorganic flocculant which

is composed of alkaline rare earth element.

・Ferric chloride

・Aluminum sulfate

・Alkaline rare earth element

Special features and effects

MSC destroys the film covering of fine particles that absorbs the water

in the soil that composes the bottom mud. It is excellent in hydrophobization

that releases a large quantity of free water in the soil particles. Hydrophobic

fine particles absorb and combine together. These will become large particles

and settles down quickly. After settling down, the particles gradually

shrink and it exerts consolidation in accordance with the increase of the

sludge volume. As a result, the water around soil particles is separated

from soil particles and will become pure supernatant water.

1.Separated water becomes supernatant water as soil particles agglutinate

and settle down quickly.

2.Increasing in hydrophobization and it is able to have space to store

large quantity of separated soil in the processing areas due to large coefficient

consolidation.

3.We can move to the second construction process early because of the consolidation

the processing areas quickly dries out and coefficient of permeability

is large.

4.The components included in the MSC is safe and will not affect the environment.

5.Separated soil is effective as a fertilizer and soil conditioner improved

by the MSC's components (iron, potassium,calcium) and nutrient salts (nitrogen,

phosphorus) in the bottom mud and microorganisms. Thus, the separated soil

is effectively reused for agricultural soil.

6.Not only the hydrophobization of organic mud (sludge), but also MSC has

an effect on aggregation sedimentation of toxic substance in the contaminated

water.

The processing of the bottom mud

Effective utilization of separated soil

Bottom mud piles up on closed water area of inland, stagnant river which

has slow current and inner bays near the sea, causing water pollution.

To improve this environment, the bottom mud is removed (dredging). Moreover,

the dredging is generally conducted to secure water shortage and ship navigation.

Dredging has been conducted in many water areas and resulted into a large

amount of bottom sludge (dredged soil). To process bottom sludge, there

are two ways to dispose. Disposal to the land and the other is disposal

to the water.

In the current condition, in order to enable to transport the dredged

soil to the land by truck, we need to consider issues of dehydration and

solidification. Also, there is the issue about deterioration of the surrounding

environment on the truck's route. The disposal to the water discards at

water side of a reclaimed land. Although a large quantity can be transported

at once by ship, there are various problems such as environmental issues

with the way of use of the reclaimed land. In the future, it is expected

that it will be hard to secure the land to be reclaimed . It is necessary

to effectively use the secured and reclaimed land.

There are a lot of problems with these conventional constructions. Not

only the problems with the sludge amount, but also the water applied by

the dredging operation and it becomes mud water, disposed on the disposal

land as it is, will require a lot of time for solid-liquid separartion

so it will need a vast disposal site.

Problems of conventional constructions

1.It is hard to decide the amount of soil that can be accepted in the disposal

land.

2.Not economical because the soil amount with self-weight settlement during

construction is difficult to know

3.As it can not figure out subsidence (soil-weight settlement) after the

reclaimed construction, it is hard to expect soil stabilization.

4.It needs to be transported and disposed as industrial waste using solidification

agent of cement materials.

Merits of MSC method

1.It can determine exactly the amount of soil to be accepted.

2.It can figure out the amount of self-weight settlement and the amount

of acceptable soil increases thus it is economical.

3.Strength of consolidation increases after the reclaimed construction.

It does not need to consider soil stabilization, thus it is economical.

4.Separated soil is recycled and can be used because it is rich soil.

|