|

MiraCarbon for contact media |

|

|

General Characteristics of Contact Media |

| ●General Characteristics of Contact Media |

●Required surface area and quantity of Tassel Contact media |

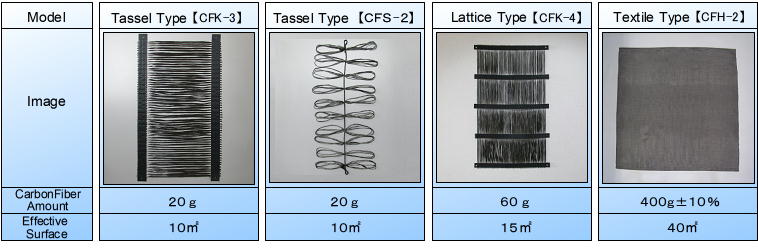

| Model |

CF amount |

Effective Surface |

| Tassel CFK-3 |

20g |

10㎡ |

| Tassel CFS-2 |

20g |

10㎡ |

| Lattice CFK-4 |

60g |

15㎡ |

| ※Textile Type |

100g |

10㎡ |

| ※ |

The effective surface of textile CarbonFIber is per 100g |

| ※ |

The weight of textile CarbonFIber is 500g/㎡ per textile area |

| ◆ |

Effective Surface :

Tassel type: 0.5 ㎡/g(CFK-3, CFS-2)

Lattice type: 0.25 ㎡/g(CFK-4)

Textile type: 0.1 ㎡/g |

| ◆ |

Surface load of sludge:50g/㎡ |

|

Surface

(/㎥) |

Tassel

CF amount |

CFK-3

CFS-2 |

Lattice

CF amount |

CFK-4

(Pc/㎥) |

| 100㎡ |

200g |

10pcs |

420g |

7pcs |

| 150㎡ |

300g |

15pcs |

600g |

10pcs |

| 200㎡ |

400g |

20pcs |

840g |

14pcs

|

| 250㎡ |

500g |

25pcs |

1,020g |

17pcs |

| 300㎡ |

600g |

30pcs |

1,200g |

20pcs |

| ※ |

The Standard of tassel type is MiraCarbon CFK-3, CFS-2. |

| ※ |

Installation method depends on MiraCarbon tassel type qty. |

| ※ |

he length of MiraCarbon lattice type is determined by water depth as CFK-4

as standard. |

| ※ |

MiraCarbon lattice type is attached to installation equipment by installing

rope |

|

|

|

|

The characteristics of CarbonFIber contact media |

●Mass adhesion of activated sludge

The filament surface is uneven, so the absorbing amount on each surface

is large. The filaments are close to each other, and it can keep mass sludge

between filaments. Because sludge gets in deep inside of the clusters,

it makes longer residence time. Thus, it can prevent waste sludge.

●Treatment by microorganism activation

Anaerobic bacteria accumulate in the deep inside of the filament cluster.

Aerobic bacteria with high activation also accumulate around it by swaying

its filament and current of water. Microorganisms activate with swaying

filament, and then organic matters such as BOD ・CODare decomposed.MiraCarbon

facilitate decomposition and removal of nutrient salts such as nitrogen

and phosphorus.

|

|

Mechanism of water purification |

◆Application consideration

1.MiraCarbon has equal to or larger total specific surface area than advanced

activated carbon. However, as contact media, pores inside of filament are

not effective for sludge adhesion, so only outside surface area is included

to calculate.

2.Because textile CarbonFiber does not spread in the water, effective surface

area decreases.

3.Large amount of sludge are attached on the uneven filament surface and

between filament.

4.Please use lattice or textile type contact media in case of faster than

0.3 m/s flow or aeration since fiber might be cut down.

5.Please refer the dedicated site for MiraCarbon, installation set, and

unit.

|

|

Specification and Application |

| Specification |

Application |

●Material: PAN Water-soluble sizing

●Filament: 7µm×12,000 or 15,000 qty

●Effective surface:Tassel type 0.5 ㎡/g

Lattice type 0.25 ㎡/g

Textile type 0.1 ㎡/g

●Weight per unit length:12K:0.8 g/m 15K:1.0 g/m |

●For activated sludge process in effluent facility

●For treatment speed, water quality, amount

●For decrease of waste sludge

●For biotreatment in food and chemical factory

●For settle and effluent tank and effluent quality

●For treatment of rivers, lake/marsh, and sea |

|

|

Contact media installation site in wastewater plant |

|